Resumen de especificaciones

-

Temperatura del proceso

-50 °C...+150 °C

(-58 °F...+302 °F) -

Presión de proceso absoluta / límite de sobrepresión máx.

Vacío...100 bar

-

Densidad min. del medio

0.5g/cm³ (0.4g/cm³ opcional)

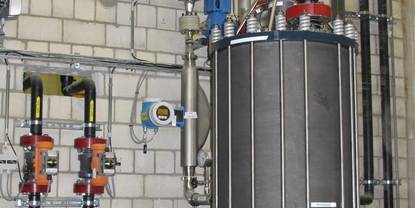

Ámbito de aplicación

Liquiphant FTL51 es un equipo de detección de nivel con tubo de extensión para uso en zonas con peligro de explosión que está dotado con todos los certificados internacionales. Para uso en todos los sectores industriales. FTL51 ofrece seguridad funcional SIL2/SIL3. La segunda línea de defensa permite garantizar el más alto nivel de seguridad y rendimiento del equipo. Valores de medición fiables insensibles a: propiedades cambiantes de los productos, caudal, turbulencias, burbujas de gas, espuma, vibraciones o adherencias.

Detección de nivel con tubo de extensión para todo tipo de líquidos.

Conexiones a proceso: roscas, bridas y conexión higiénica (Triclamp)

Temperatura: -50 a +150 °C (-58 a +302°F)

Presión: -1 a +100 bar (-14,5 a +1.450 psi)

Material del sensor: 316L, Alloy

Certificados internacionales de protección contra explosión, WHG, SIL.

Ventajas

Uso en sistemas de seguridad que requieren seguridad hasta SIL2/SIL3 según

IEC 61508/IEC 61511-1Certificados internacionales de protección contra explosiones y prevención de reboses (WHG)

No necesita calibración, fácil de poner en marcha

Sin partes mecánicas móviles: sin mantenimiento, sin desgaste, larga vida útil.Monitorización de daños en la horquilla: funcionamiento garantizado

Segunda línea de defensa para proteger el medio ambiente

Diversidad de conexiones a proceso para todas las aplicaciones

Material del sensor de alta resistencia a la corrosión (Alloy) de acero inoxidable (316L)

Vídeos

Gama Extended

-

Productos de alta gama

- Altamente funcionales y prácticos

Excelencia técnica

Simplicidad

-

Productos estándar

- Seguros, resistentes y con poco mantenimiento

Excelencia técnica

Simplicidad

-

Productos de alta gama

- Altamente funcionales y prácticos

Excelencia técnica

Simplicidad

-

Productos especializados

- Diseñados para aplicaciones exigentes

Excelencia técnica

Simplicidad

Variable

| Gamas FLEX | Excelencia técnica | Simplicidad |

|---|---|---|

Gama Fundamental Satisfaga sus necesidades básicas de medición |

Excelencia técnica

|

Simplicidad

|

Gama Lean Maneje los principales procesos fácilmente |

Excelencia técnica

|

Simplicidad

|

Gama Extended Optimice sus procesos con tecnologías innovadoras |

Excelencia técnica

|

Simplicidad

|

Gama Xpert Domine las aplicaciones más exigentes |

Excelencia técnica

|

Simplicidad

Variable |

Loading alternative products

Loading alternative products

Predecesor

-

-

Manual de instrucciones (BA)

Liquiphant M/S FTL50, FTL51, FTL50H, FTL51H, FTL51C, FTL70, FTL71 Electronic insert FEL50A PA

Versión en inglés - 08/2004

Vibration Limit Switch Level limit switch for all liquids. Suitable for use in hazardous areas, food and pharmaceuticals

EN ES 10/08/2004Idioma:

Inglés

Versión:

10/08/2004

Tamaño del archivo:

836 KB

Nombre del archivo:

BA141FEN.pdf

-

-

-

Información técnica (TI)

Liquiphant M FTL50, FTL51, FTL50H, FTL51H Technical Information

Versión en español - 01/2020

Point level switch for all kinds of liquids

EN ES 10/01/202009/10/201730/11/201607/05/201504/04/2012Idioma:

Español

Versión:

10/01/2020

Tamaño del archivo:

1.7 MB

Nombre del archivo:

TI00328FES_1820.pdf

-

-

-

Información técnica (TI)

TI Weld-in adapter, process adapter and flanges

Level, pressure and temperature measurement

EN ES 06/12/202404/04/202425/03/202415/09/202328/10/2021Idioma:

Español

Versión:

06/12/2024

Tamaño del archivo:

1.3 MB

Nombre del archivo:

TI00426FES_2624.pdf

-

-

-

Información técnica (TI)

Liquiphant M FTL50, FTL51, FTL50H, FTL51H Technical Information

Point level switch for all kinds of liquids

EN ES 10/01/202009/10/201730/11/201607/05/201504/04/2012Idioma:

Español

Versión:

10/01/2020

Tamaño del archivo:

1.7 MB

Nombre del archivo:

TI00328FES_1820.pdf

-

-

-

Información técnica (TI)

Liquiphant M FTL51C Technical Information

Point level switch for all kinds of liquids

with high corrosion-resistant coatingEN ES 31/08/201813/02/201719/05/201029/11/2007Idioma:

Español

Versión:

31/08/2018

Tamaño del archivo:

943.6 KB

Nombre del archivo:

TI00347FES_1418.pdf

-

-

-

Información técnica (TI)

Liquiphant M de densidad y calculador de densidad FML621 Información técnica

Calculador de densidad para líquidos.

También apto para zonas con peligro de explosión.EN ES 08/10/201212/02/200929/11/2007Idioma:

Español

Versión:

12/02/2009

Tamaño del archivo:

3.7 MB

Nombre del archivo:

TI420Fes_v0209.pdf

-

-

-

Manual de instrucciones (BA)

Liquiphant M/S FTL50, FTL51, FTL50H, FTL51H, FTL51C, FTL70, FTL71 Electronic insert FEL50A PA

Vibration Limit Switch

Level limit switch for all liquids.

Suitable for use in hazardous areas, food and pharmaceuticalsEN ES 10/08/2004Idioma:

Inglés

Versión:

10/08/2004

Tamaño del archivo:

836 KB

Nombre del archivo:

BA141FEN.pdf

-

-

-

Instrucciones breves (KA)

Bedienungsanleitung/ Operating Instuction Liquiphant.

Sliding Sleeve

EN ES 01/05/200801/11/1998Idioma:

Inglés

Versión:

01/05/2008

Tamaño del archivo:

314.8 KB

Nombre del archivo:

KA100fa6_0308.pdf

-

-

-

Instrucciones breves (KA)

Liquiphant M FTL50, FTL51 Operating Instructions

Point level switch for all kinds of liquids

EN ES 20/01/201729/06/201618/04/200601/04/2006Idioma:

Inglés

Versión:

20/01/2017

Tamaño del archivo:

982.5 KB

Nombre del archivo:

KA00143FA6_1417.pdf

-

-

-

Instrucciones breves (KA)

FTL5x - Exchange of housing F13

Liquiphant FTL5x - Exchange of housing F13

EN ES 15/04/2021Idioma:

Inglés

Versión:

15/04/2021

Tamaño del archivo:

232.8 KB

Nombre del archivo:

KA00531F00_A2.pdf

-

-

-

Instrucciones breves (KA)

Exchange of sensor on Liquiphant M/S

Exchange of sensor on Liquiphant M/S

EN ES 24/04/2012Idioma:

Inglés

Versión:

24/04/2012

Tamaño del archivo:

398.2 KB

Nombre del archivo:

KA00529FA2_0908.pdf

-

-

-

Instrucciones breves (KA)

Liquiphant M Density FTL50, FTL51 Operating Instructions

Liquiphant M for density and concentration calculation

EN ES 29/06/201615/11/2007Idioma:

Inglés

Versión:

29/06/2016

Tamaño del archivo:

999.4 KB

Nombre del archivo:

KA00284FA6_1316.pdf

-