Pressure measurement is a fundamental technology for monitoring process conditions in tanks and pipelines. Because the media differ in their properties, different pressure measurement principles are applied: absolute and gauge pressure, hydrostatic pressure, and differential pressure.

In absolute and gauge pressure measurement, the process pressure deflects a diaphragm. This force is transmitted via incompressible oil to a silicon chip, where it is converted into an electrical signal. The difference lies in the reference point: absolute pressure is measured against a vacuum, while gauge pressure is measured relative to ambient air. Hydrostatic level measurement relies on the weight of the liquid column. As the filling level increases, gravity causes the pressure on the sensor diaphragm to rise proportionally to the height and density of the medium. In differential pressure measurement, two pressure values are recorded, typically in a closed tank. The transmitter calculates the difference to determine the level or pressure inside the tank.

Watch the video to learn how pressure measurement works.

Advantages of Cerabar, Ceraphant, Deltabar, Deltapilot and Waterpilot at a glance

- Continuous pressure and level measurement for liquids and gases

- High measurement accuracy and long-term stability

- Robust design for harsh process conditions

- Versatile sensor portfolio for flexible system integration

- Proven reliability across a wide range of industrial applications

The most varied media are filled into and drained via pipes from tanks every day. Examples are potable water, fruit juices, oils and fuels, acids or brines. Since these media can have completely different properties, there are different measuring principles to detect them. For example, pressure measurement by absolute or gauge pressure, hydrostatic pressure, as well as differential pressure.

The first scientific origins of pressure measurement were documented in the middle of the 17th century. Galileo Galilei made tests with pumps to overcome the differences in altitude for irrigation purposes. Evangelista Torricelli conducted research with mercury columns and discovered the state of the vacuum. Blaise Pascal heard of these experiments, continued the research and could determine the weight of air. Pascal called this force pressure, and to pay homage to him, the SI unit for pressure was named after him. Pressure is the result of a force acting on an area.

Pressure instruments may be used to detect absolute and gauge pressures and to determine pressure variables and levels in tanks. First of all, let's have a closer look at the mode of operation of this measuring method using the example of absolute and gauge pressure.

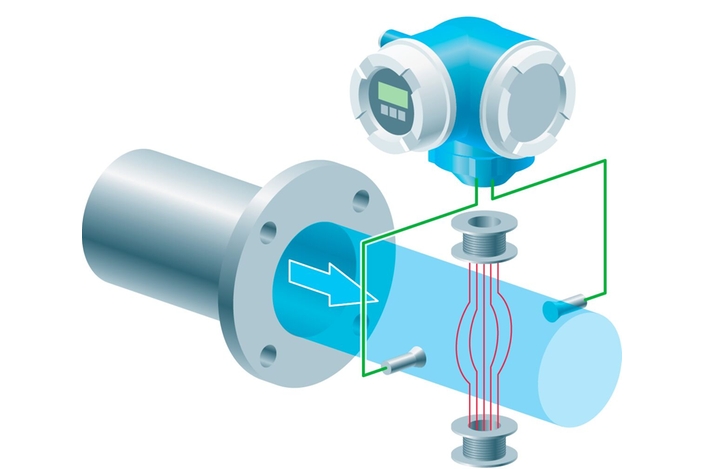

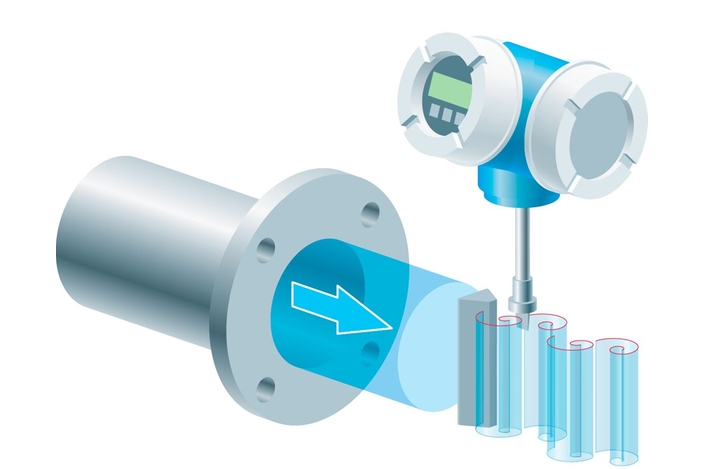

Pressures can be measured continually in a pipe flooded with a liquid. We will have a closer look at the difference of an absolute pressure cell and a gauge pressure cell using the example of a ceramic cell. In a ceramic cell, an electrically conductive material is applied to a ceramic substrate, thus forming a capacitor. As pressure is applied, the diaphragm deforms and causes a change in capacitance.

The absolute pressure cell is a closed system and measures against the vacuum in an atmospheric environment, the air pressure is indicated. In a gauge pressure cell, an opening in the substrate permits the pressure compensation between the atmospheric environment and the inside of the cell.

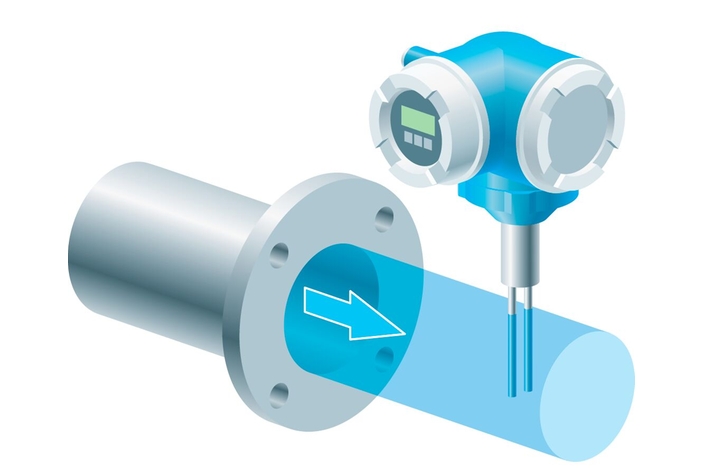

The cell measures values which are relative to the ambient pressure. In an atmospheric environment, the air pressure is not indicated. In hydrostatic pressure measurement, the liquid in the tank acts on the process diaphragm of the sensor. Gravity causes the pressure to increase as the liquid column, that is, the filling level of the tank, rises. The liquid column is proportional to the filling level and the density of the medium.

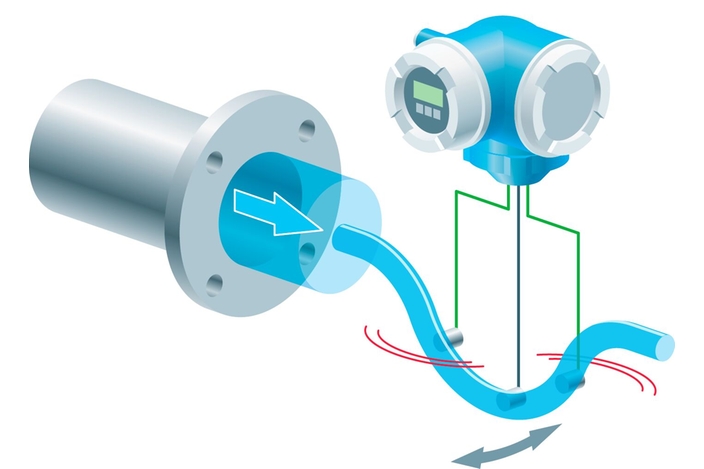

In an open tank, pressure is continually compensated in relation to ambient air. Therefore, the gas in the upper area of the tank does not affect level measurement. However, in addition to the pressure of the liquid column, the atmospheric pressure also acts on the sensor. In atmospheric pressure compensation, the sensor is called a gauge pressure sensor. Let's have a closer look at such a sensor. The contact measuring cell is based on silicon technology and has been particularly developed for hydrostatic level measurement. Resistances are applied to a silicon chip in form of a Wheatstone bridge.

As pressure is applied, the process diaphragm is deformed and a change in resistance results. In the sensor, incompressible oil transmits the pressure from the process diaphragm to a silicon chip where it is analyzed. In differential pressure measurement in a closed tank, the atmospheric pressure is of no consequence for level measurement. Apart from the pressure of the liquid column, the pressure head above the level is also measured. Both values are transferred to the transmitter via oil-filled capillary lines. The transmitter calculates the difference between both pressures and determines the level in the tank from this value.

The pressure instruments of Endress+Hauser facilitate the measurement of pressures and levels in standard applications, as well as applications with high temperatures and high pressures, as well as those involving corrosive and abrasive media. We have an appropriate solution for any application. Endress+Hauser.